Slots Slats Flaps

Posted : admin On 4/1/2022- Slots Slats Flaps For Dodge Ram

- Slots Slats Flaps For Sale

- Slots Slats Flaps For Jeep

- Slots Slats Flaps Home Depot

Nov 20, 2018 The part on the leading edge is called a slat, while the part on the trailing edge is called a flap. The flaps and slats move along metal tracks built into the wings. Moving the flaps aft (toward the tail) and the slats forward increases the wing area. Slat (note it is extending the airfoil. Flaps in reverse if it were) slot (not it is only keeping air attached to the airfoil at high AOA) Last edited by Toysrme; Mar 10, 2012 at 09:31 AM.

secondary flight controlsIn addition to primary flight controls, most airplanes have another group called secondary controls. These include trim devices of various types and wing flaps. The trim devices are adjusted so that the aircraft remains balanced in flight.

Flaps

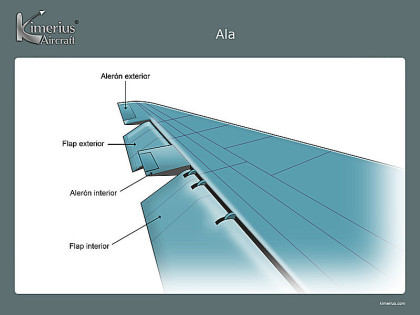

Flaps are moveable surfaces on the trailing edge of the wing similar in shape to the ailerons. they are usually larger in surface area. They are located on inboard end if the wing next to the fuselage. Both sides are activated together so they do not produce a rolling action like the ailerons.

Flaps are usually deployed in 'degree' increments. In small aircraft deployment is usually in 10 degree increments from zero degrees (non-deployed) to 40 degrees maximum. Larger or more sophisticated aircraft may have a different range of settings. Normally, the flaps operate electrically through a 4 or 5 position switch located on the instrument panel. In earlier aircraft the flaps were operated using a manual flap handle.

Deployment of flaps increases both the lift and drag of the wing. Flap activation increases the angle of attack across the wing / flap section. At 10 degrees, more lift than drag is produced. As the flap angle is increased more drag and less lift is produced for each increment of deployment.

The primary use of flaps is in landing. They permit a steeper decent without increase in airspeed. Flaps may be used in certain take-off situations (usually 10°) on short or soft fields.

Flaps are now fitted to most aircraft because:

They permit a slower landing speed, which decreases the required landing distance.

They permit a comparatively steep angle of descent without an increase in speed. This makes it possible to safely clear obstacles when making a landing approach to a small field.

They may also be used to shorten the takeoff distance and provide a steeper climb path.

VFE

This term describes the maximum velocity at which flaps can be deployed. The VFE is shown on the air speed indicator as the top end of the white arc.

Flaps are high lift devices which, in effect, increase the camber of the wing and, in some cases, as with the Fowler Flap, also increase the effective wing area. Their use gives better take-off performance and permits steeper approach angles and lower approach and landing speeds.

When deflected, flaps increase the upper camber of the wing, increasing the negative pressure on the top of the wing. At the same time, they allow a build up of pressure below the wing. During take-off, flap settings of 10 degrees to 20 degrees are used to give better take-off performance and a better angle of climb, especially valuable when climbing out over obstacles.

However, not all airplane manufacturers recommend the use of flaps during take-off. They can be used only on those airplanes, which have sufficient take-off power to overcome the extra drag that extended flaps produce. The recommendations of the manufacturer should, therefore, always be followed.

Flaps do indeed increase drag. The greater the flap deflection. the greater the drag. At a point of about half of their full travel, the increased drag surpasses the increased lift and the flaps become air brakes. Most flaps can be extended to 40 degrees from the chord of the wing. At settings between 20 degrees and 40 degrees, the essential function of the flaps is to improve the landing capabilities, by steepening the glide without increasing the glide speed. In an approach over obstacles, the use of flaps permits the pilot to touch down much nearer the threshold of the runway. Flaps also permit a slower landing speed and act as air brakes when the airplane is rolling to a stop after landing, thus reducing the need for excessive braking action. As a result, there is less wear on the undercarriage, wheels and tires. Lower landing speeds also reduce the possibility of ground looping during the landing roll.

Plain and split flaps increase the lift of a wing, but at the same time, they greatly increase the drag. For all practical purposes, they are of value only in approach and landing. They should not normally be employed for take-off because the extra drag reduces acceleration.

Slotted flaps, on the other hand, including such types as Fowler and Zap, produce lift in excess of drag and their partial use is therefore recommended for take-off.

From the standpoint of aerodynamic efficiency, the Fowler Flap is generally considered to offer the most advantages and the fewest disadvantages, especially on larger airplanes, while double slotted flaps have won wide approval for smaller types.

On STOL airplanes, a combination of double slotted flaps and leading edge slats are common.

Changes in flap setting affect the trim of an airplane. As flaps are lowered, the centre of pressure moves rearward creating a nose down, pitching moment. However, in some airplanes, the change in airflow over the tailplane as flaps are lowered, is such that the total moment created is nose up and it becomes necessary to trim the airplane 'nose down'.

The airplane is apt to lose considerable height when the flaps are raised. At low altitudes, therefore, the flaps should be raised cautiously.

Most airplanes are placarded to show a maximum speed above which the flaps must not be lowered. The flaps are not designed to withstand the loads imposed by high speeds. Structural failure may result from severe strain if the flaps are selected 'down' at higher than the specified speed.

When the flaps have been lowered for a landing, they should not ordinarily be raised until the airplane is on the ground. If a landing has been missed, the flaps should not be raised until the power has been applied and the airplane has regained normal climbing speed. It is then advisable to raise the flaps in stages.

How much flap should be used in landing? Generally speaking, an airplane should be landed as slowly as is consistent with safety. This usually calls for the use of full flaps. The use of flaps affects the wing airfoil in two ways. Both lift and drag are increased. The Increased lift results in a lower stalling speed and permits a lower touchdown speed. The increased drag permits a steeper approach angle without increasing airspeed. The extra drag of full flaps results in a shorter landing roll.

An airplane that lands at 50 knots with full flaps selected may have a landing speed as fast as 70 knots with flaps up. If a swerve occurs during the landing roll, the centrifugal force unleashed at 70 knots is twice what it would be at 50 knots, since centrifugal force increases as the square of the speed. It follows then, that a slower landing speed reduces the potential for loss of control during the landing roll. It also means less strain on the tires, brakes and landing gear and reduces fatigue on the airframe structure.

There are, of course, factors, which at times call for variance from the procedure of using full flaps on landing. These factors would include the airplane's all-up-weight, the position of the C.G., the approach path to landing, the desired rate of descent and any unfavourable wind conditions, such as a strong cross wind component, gusty winds and extreme turbulence. With experience, a

pilot learns to assess these various factors as a guide to flap selection.

In some airplanes, in a crosswind condition, the use of full flap may be inadvisable. Flaps present a greater surface for the wind to act upon when the airplane is rolling on the ground. The wing on the side from which the wind is blowing will tend to rise. In addition, cross wind acting on full flaps increases the weather vaning tendencies, although in an airplane with very effective rudder control even at slow speeds, the problem is not so severe. However, in many airplanes, the selection of full flaps deflects the airflow from passing over the empennage, making the elevator and rudder surfaces ineffective. Positive control of the airplane on the ground is greatly hampered. Since maintaining control of the airplane throughout the landing roll is of utmost importance, it may be advisable to use less flaps in cross wind conditions. In any case, it is very important to maintain the crosswind correction throughout the landing roll.

trim tabsA trim tab is a small, adjustable hinged surface on the trailing edge of the aileron, rudder, or elevator control surfaces. Trim tabs are labour saving devices that enable the pilot to release manual pressure on the primary controls.

Some airplanes have trim tabs on all three control surfaces that are adjustable from the cockpit; others have them only on the elevator and rudder; and some have them only on the elevator. Some trim tabs are the ground-adjustable type only.

The tab is moved in the direction opposite that of the primary control surface, to relieve pressure on the control wheel or rudder control. For example, consider the situation in which we wish to adjust the elevator trim for level flight. ('Level flight' is the attitude of the airplane that will maintain a constant altitude.) Assume that back pressure is required on the control wheel to maintain level flight and that we wish to adjust the elevator trim tab to relieve this pressure. Since we are holding back pressure, the elevator will be in the 'up' position. The trim tab must then be adjusted downward so that the airflow striking the tab will hold the elevators in the desired position. Conversely, if forward pressure is being held, the elevators will be in the down position, so the tab must be moved upward to relieve this pressure. In this example, we are talking about the tab itself and not the cockpit control.

Rudder and aileron trim tabs operate on the same principle as the elevator trim tab to relieve pressure on the rudder pedals and sideward pressure on the control wheel, respectively.

The tabs are usually controlled by a wheel which is often situated on the floor between the two front seats. Some aircraft have the trim controlled by a small rocker switch on the control column. The aircraft should be trimmed after every change in attitude or power setting. It takes a little practice to trim an aircraft, but in the end it is done unconsciously.

other wing additions

Slots Slats Flaps For Dodge Ram

The type of operation for which an airplane is intended has a very important bearing on the selection of the shape and design of the wing for that airplane. Wing fences, slots, slats, spoilers, speed brakes and flaps are additions to the wing that perform a variety of functions related to control of the boundary layer, increase of the planform area (thus affecting lift and drag) and reduction of aircraft velocity during landing and stopping.

wing fences

Wing fences are fin-like vertical surfaces attached to the upper surface of the wing, that are used to control the airflow. On swept wing airplanes, they are located about two-thirds of the way out towards the wing tip and prevent the drifting of air toward the tip of the wing at high angles of attack. On straight wing airplanes, they control the airflow in the flap area. In both cases, they give better slow speed handling and stall characteristics.

slots

Slats are auxiliary airfoils fitted to the leading edge of the wing. At high angles of attack, they automatically move out ahead of the wing. The angle of attack of the slat being less than that of the mainplane, there is a smooth airflow over the slat which tends to smooth out the eddies forming over the wing. Slats are usually fitted to the leading edge near the wing tips to improve lateral control. The Socata Rallye is an example of a light aircraft that utilizes leading edge slats.

Slots are passageways built into the wing a short distance from the leading edge in such a way that, at high angles of attack, the air flows through the slot and over the wing, tending to smooth out the turbulence due to eddies.

spoilers

spoiler on an F4 Phantom wing

Spoilers are devices fitted to the wing which increase drag and decrease lift. They usually consist of a long narrow strip of metal arranged spanwise along the top surface of the airfoil. In some airplanes, they are linked to the ailerons and work in unison with the ailerons for lateral control. As such, they open on the side of the upgoing aileron, spoil the lift on that wing and help drive the wing down and help the airplane to roll into a turn.

In some airplanes, spoilers have replaced ailerons as a means of roll control. The spoiler moves only upward in contrast to the aileron that moves upward to decrease lift and downward to increase lift. The spoiler moves only up, spoiling the wing lift. By using spoilers for roll control, full span flaps can be used to increase low speed lift.

Spoilers can also be connected to the brake controls and. when so fitted, work symmetrically across the airplane for producing drag and destroying lift after landing, thereby transferring all the weight of the airplane to the wheels and making braking action more effective.

speed brakes

RF-84K Thunderflash speed brake

Speed brakes are a feature on some high performance airplanes. They are a device designed to facilitate optimum descent without decreasing power enough to shock cool the engine and are especially advantageous in airplanes with high service ceilings. They are also of use in setting up the right approach speed and descent pattern in the landing configuration. The brakes, when extended, create drag without altering the curvature of the wing and are usually fitted far enough back along the chord so as not to disrupt too much lift and in a position laterally where they will not disturb the airflow over the tailplane. They are usually small metal blades housed in a fitting concealed in the wing that, when activated from the cockpit, pivot up to form a plate. On some types of aircraft, speed brakes are incorporated into the rear fuselage and consist of two hinged doors that open into the slipstream.

- 2Common types

- 2.2Movable slats

Introduction

High lift devices are movable surfaces or stationary components that are designed to increase lift during some phases or conditions of flight. It is most frequently utilised during takeoff and initial climb and the approach and landing phases of flight, but may also be used in any other low speed situation. They accomplish this by increasing both the surface area and the camber of the wing. The leading edge of the airfoil can also be equipped with high lift devices.

Common types

Slots Slats Flaps For Sale

The most common types of leading edge high lift devices are fixed slots, movable slats, leading edge flaps and cuffs.

Fixed slots

Fixed slots direct airflow to the upper wing surface and delay airflow separation at higher angles of attack. The slot does not increase the wing camber, but allows a higher maximum lift because the stall is delayed until the wing reaches a greater angle of attack.

A good example of an aircraft which uses fixed slots is the Zenith CH750, light utility airplane.

Movable slats

Movable slats consist of leading edge segments that move on tracks. It can be either automatic, or powered and controlled by a pilot.

Slots Slats Flaps For Jeep

Automatic slats

Slots Slats Flaps Home Depot

They open and close aerodynamically. When air approaches the leading edge of an airfoil, it divides; some flowing over the top of the wing and some flowing over the bottom. The spot where the airflow splits is called the 'stagnation point. 'When the airfoil is at a low angle of attack, the stagnation point is on the leading edge. When the airfoil is at a high angle of attack, the stagnation point moves below the leading edge and behind the slat. Air flowing up and over the wing pushes the slat open.

For example, a German Bf-109 fighter uses automatic flaps.

Powered slats

They appear on many large aircraft and provide the same benefits as an automatic slat. However, they are electrically or hydraulically powered - increasing reliability. The flight crew sets the slat position via cockpit controls.

For example, this is how powered slats look like on a Boeing 737.

Leading edge flaps

Leading edge flaps, like trailing edge flaps, are used to increase both the lift coefficient and the camber of the wing. This type of leading edge device is frequently used in conjunction with trailing edge flaps and can reduce the nose-down pitching movement produced by the latter. As is true with trailing edge flaps, a small increment of leading edge flaps increases lift to a much greater extent than drag. As flaps are extended, drag increases at a greater rate than lift.

As an example, leading edge flaps on the wing root of a B737-200.

Cuffs

Leading edge cuffs, like leading edge flaps and trailing edge flaps, are used to increase both CL-MAX and the camber of the wings. Unlike leading edge flaps and trailing edge flaps, leading edge cuffs are fixed aerodynamic devices. In most cases, leading edge cuffs extend the leading edge down and forward. This causes the airflow to attach better to the uppersurface of the wing at higher angles of attack, thus lowering an aircraft’s stall speed. The fixed nature of leading edge cuffsextracts a penalty in maximum cruise airspeed, but recent advances in design and technology have reduced this penalty.

The best modern example of cuffs is used on the Cirrus SR-20/22.

See also

Reference

- Pilot’s Handbook of Aeronautical Knowledge by FAA - Chapter 6 Flight controls

- SKYbrary library - High lift devices

- boldmethod.com

Author

- 531824 - Creation

DATE OF SUBMISSION

- 03:59, 10 December 2020

COPYRIGHT

- This documentation is copyrighted as part of the intellectual property of the International Virtual Aviation Organisation.

DISCLAIMER

- The content of this documentation is intended for aviation simulation only and must not be used for real aviation operations.